|

New Innovative Design

The BMRX has been designed to provide security from system power failure, easy access to all components, and reliability through advanced circuitry.

Principle of Operations

The BMRX has few moving parts and features simple and dependable operation. A slow speed synchronous motor rotates a paddle which senses the presence of material at the level where the BMRX is placed.

At a high level control the paddle rotates continually when the material is not present. When the material reaches the paddle, the resistance causes the motor to "de-energize". This promptly causes the relay to change status and automatically shut-off any process system wired to the relay. As a low level control the paddle is stopped and the motor is "de-energized" when material is present. When material drops below the paddle the motor "energizes" and the paddle starts rotating. This causes the relay to change status and automatically start-up any process system wired to the relay.

Applications

The BMRX is designed for controlling dry bulk material storage and flow in bins, hoppers, tanks, chutes and conveyors. Typical applications include feed, cement, grain, plastics, aggregates and wood products. The BMRX can be used in materials with a bulk density as low as 2 lb/ft³ (30 kg/m³). By managing material storage and flow with the BMRX, you prevent bin overflows, empty conditions, clogged chutes, and jammed conveyors. This eliminates costly spills. material waste, and unnecessary down time.

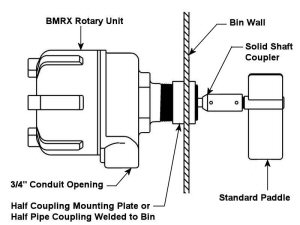

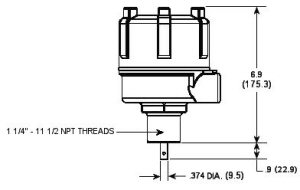

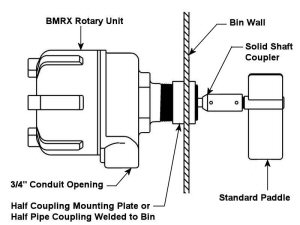

Side-Mount Installation

Side-of-bin mounting is recommended using a BinMaster half coupling mounting plate or 1/2 of a standard pipe coupling installed flush with the inside of the bin wall. A short solid shaft coupler is connected to the power pac. Paddle should be placed out of the direct flow of the material. When this cannot be avoided, a protective shield over the paddle is recommended.

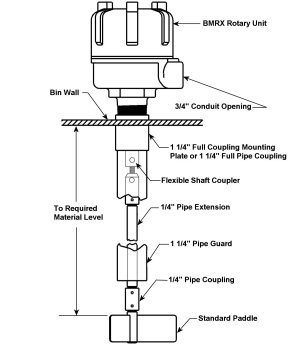

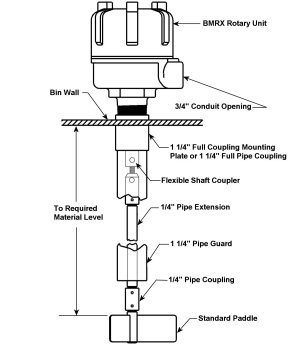

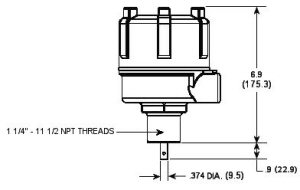

Top-Mount Installation

Top-of-bin mounting is recommended using a BinMaster full coupling mounting plate or a standard 1 1/4 pipe coupling. The length of the extension shaft (1/4 pipe) is extended to suit the application. A flexible coupler connects the shaft to the power pac. Protective shaft guards are necessary on shaft extensions 24 or longer. The shaft guard should be adequately braced on longer shaft extensions.

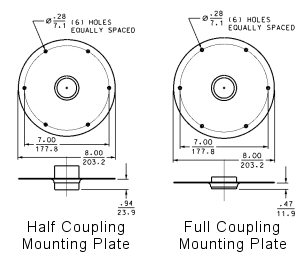

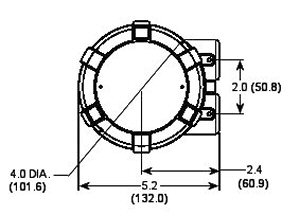

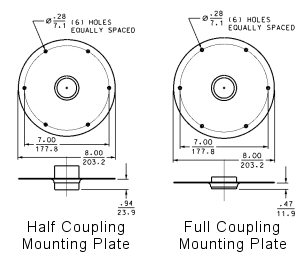

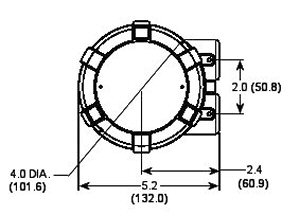

Mounting Plates

Mounting Plates Mounting plates allow the BMRX rotary units to be mounted from the outside of a vessel on a curved or flat surface. A half coupling mounting plate is used in side mount installations. A full coupling mounting plate is for use in top mount installations where a shaft extension and shaft guards are required. Both mounting plates are available in powder coated carbon steel and stainless steel for use in corrosive environments.

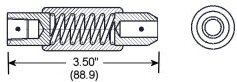

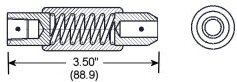

Solid Shaft Coupler

Short solid shaft coupler should be used in side mount installations. It provides stability and protects the internal workings of the unit.

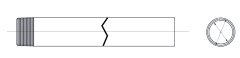

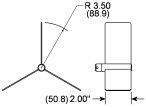

Flexible Shaft Coupler

The flexible coupler should be used in top mount installations to absorb side loads and protect the internal workings of the unit.

Pipe Extension

Top mount installation may require that the paddle extends into the vessel. Galvanized or stainless 1/4 diameter steel shaft extensions are available in a variety of lengths up to 144 (3.3 m).

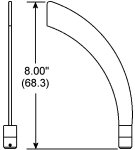

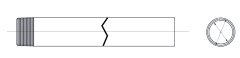

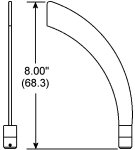

Pipe Guard

Pipe guards are recommended in top mount installations when the pipe extensions exceeds 24 ( mm). Pipe guards limit the movement of the pipe extension caused by side loading that can damage the rotary unit. Pipe guard should be the same length as the pipe extension and are available in galvanized or stainless steel.

Paddle Assemblies

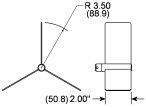

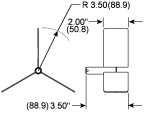

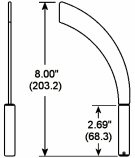

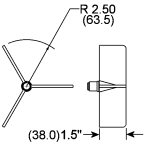

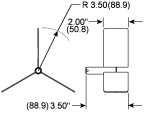

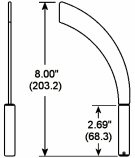

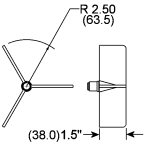

GRP-1

Stainless steel for light materials up to 30 lb/ft³. 3 vane paddle, 7” diameter. |

|

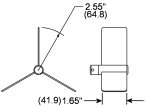

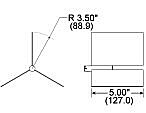

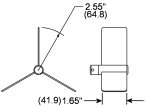

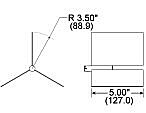

GRP-2

Stainless steel for medium materials 30 to 70 lb/ft³. 3 vane paddle, 5” diameter. |

|

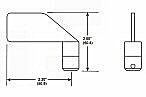

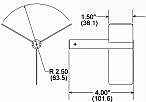

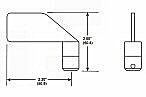

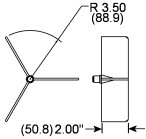

GRP-3

Insertable stainless steel for heavy materials over 60 lb/ft³. Single vane, 5” diameter. |

|

GRP-26

Direct connect (eliminates the need for GRSS-1 coupler). Version of GRP-1 |

|

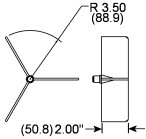

GRP-23

Insertable stainless steel paddle for medium materials 30 to 70 lb/ft³. Single bayonet vane paddle, 5” diameter. |

|

GRP-27

Direct connect (eliminates the need for GRSS-1 coupler). Version of GRP-23 paddle |

|

GRP-28

Direct connect (eliminates the need for GRSS-1 coupler). Version of GRP-23 paddle. |

|

GRP-30

Direct connect (eliminates the need for GRSS-1 coupler). Version of GRP-2.

|

|

GRP-11

Economical polyethylene paddle for light materials up to 30 lb/ft³. 3 vane paddle, 7” diameter. |

|

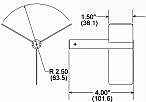

GRP-12

Economical polyethylene paddle for medium materials 30 to 70 lb/ft³. 3 vane paddle, 5” diameter |

|

GRP-24

12” Belt paddle for use in heavy material with large particulate size. |

|

Mechanical

|

Brochure

Brochure