|

|

|

NEW from BinMaster - 3D Level Scanner!

----Click for automated presentation-----

|

|

3D Level Scanner

The 3D Level Scanner uses non-contact, dust penetrating technology to create a visual map of the material surface in storage and process bins. It measures the material surface at multiple points to accurately calculate the volume and mass, even in conditions where the material surface is highly irregular. The 3D Level Scanner operates at extremely low frequencies, allowing it to penetrate through high moisture and dust with very little loss of signal power. The processor obtains signals based upon the estimated times of arrival and direction of received echoes, and generates a 3-dimensional image of the surface that can be displayed on a remote screen. Whereas most technologies measure with a single point time-of-flight, the 3D Level Scanner uses both time-of-flight and direction using three independent channels to transmit and receive which enables it to make highly accurate measurements.

The 3D Level Scanner can work in small to very large bins and can measure up to 200 tall and 150 wide. It is versatile and can accommodate a wide variety of vessels or containers including open bins, bulk storage rooms and warehouses. The 3D Level Scanner is offered in three models S for single point level measurement, M which adds mapping capabilities, and MV with both mapping and visualization graphics tools for flexibility for any application and budget. Suited for most powder or bulk solid material, it is proven to perform in coal, cement, aggregates, flyash, chemicals, fertilizers, food, grain, plastic pellets and powders. Any industry requiring accurate, non-contact measurement technology will benefit including feed, grain and seed; cement, aggregates and concrete; fertilizer; milling and food manufacturing; biofuels and ethanol; chemicals and pharmaceuticals; plastics manufacturing; power; mining and quarries; paper and wood pulp; primary metals and power.

|

|

|

3D Level Manager Software

The 3D Level Scanner can measure the level, volume and mass of powder and bulk solid materials in almost any kind of container including large bins, bulk solids storage rooms and warehouses. It measures the material level at many points throughout the bin, and then calculates the volume and mass of powder and bulk solids.

Each 3D Level Scanner comes with the 3D Level Manager software appropriate for the model purchased. The software is used to load individual bin parameters and information regarding the material being measured, to ensure that measurement data is accurate. The software displays measurement results and creates a historical log of measurements that can be used for analysis and inventory planning purposes. For the "M" and "MV" versions of the software, the 3D Level Manager Software also creates a visual map of the physical surface of the material.

Mapping capability is ideal for bins where material fills the bin unevenly making the topography of the bin highly irregular such as bins with multiple filling sites, very large bins, or for materials that tend to pile or clump. 3D Level Scanner is proven to perform even in extremely dusty environments, where other technologies have failed to work reliably. Plus, it is great for non-contact situations where you want to prevent the measurement device from touching the material such as foods or highly corrosive materials.

|

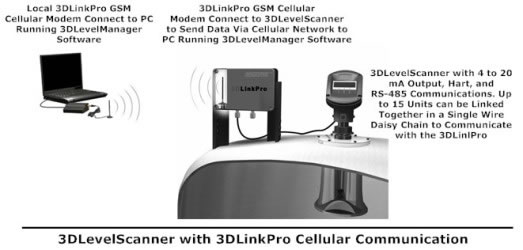

3D Link Pro

For users that desire remote GSM communications with 3D Level Scanners, the 3D Link Pro can be used to perform remote configuration of the 3D Level system, provide data to a remote location for inventory analysis purposes, to conduct remote monitoring of 3D Level system performance, and perform remote software upgrades.

|

|

|

|